Quality Assurance – Precision, Reliability & Compliance

At Joseph & Jesse Siddons Ltd, we are committed to delivering iron castings of the highest quality, targeting zero defects at the customer’s end and achieving right-first-time results on all new jobs.

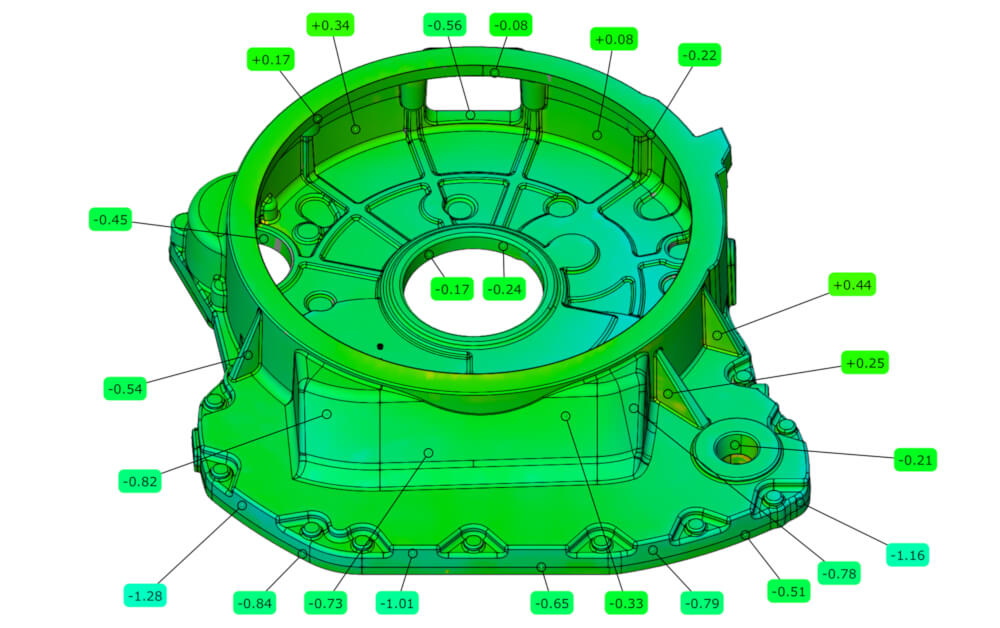

We maintain rigorous quality control processes at every stage of production, from material selection to final inspection. Our ISO 9001:2015 certification and Lloyd’s Register approval reflect our unwavering commitment to excellence, compliance, and continuous improvement.

Accreditations & Certifications

Thanks to our ISO 9001:2015 and Lloyd’s Register accreditations, we are also able to offer 3.2 certification with Bureau Veritas, DNV and TUV Nord through their equivalence agreements.

In-House Quality Control & Testing Capabilities

Additional Testing & Inspection Services

For customers requiring additional verification, we can offer specialist testing services through UKAS-accredited laboratories and trusted industry partners:

Let’s Talk Castings

Get in touch to explore our capabilities and find the right solution for your needs.

T : +44 (0)121 556 0218

E : [email protected]